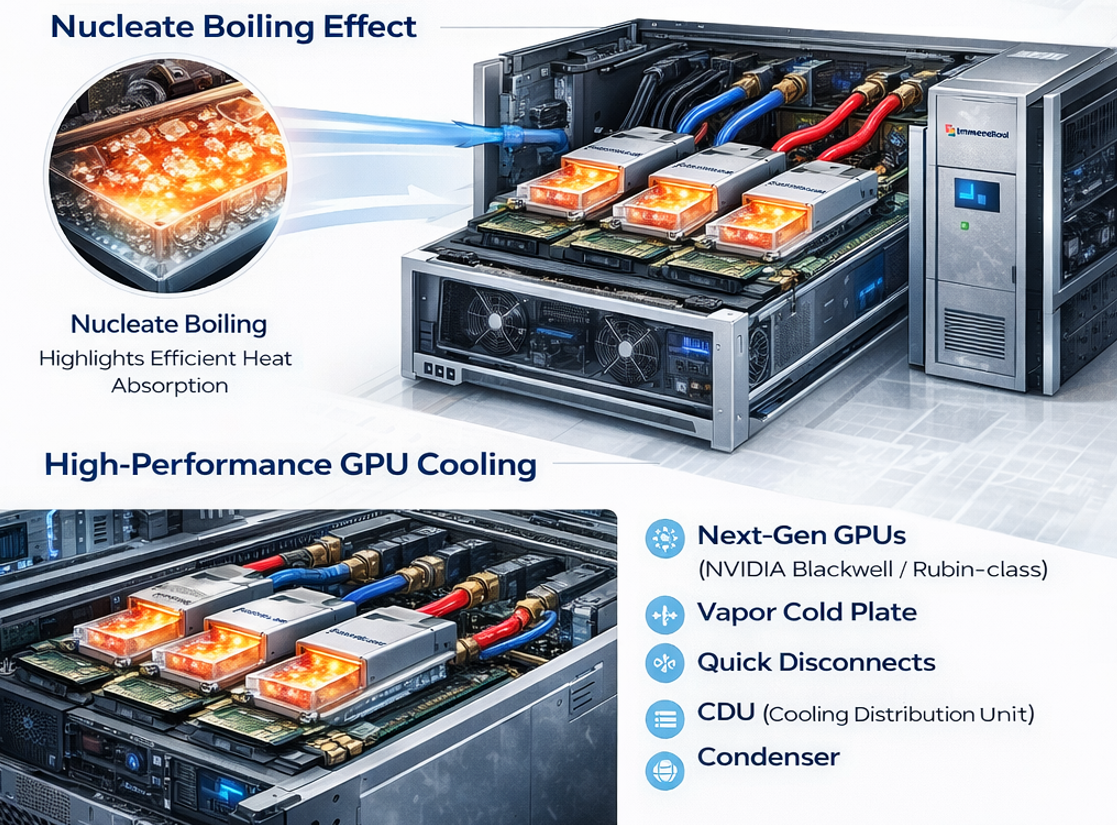

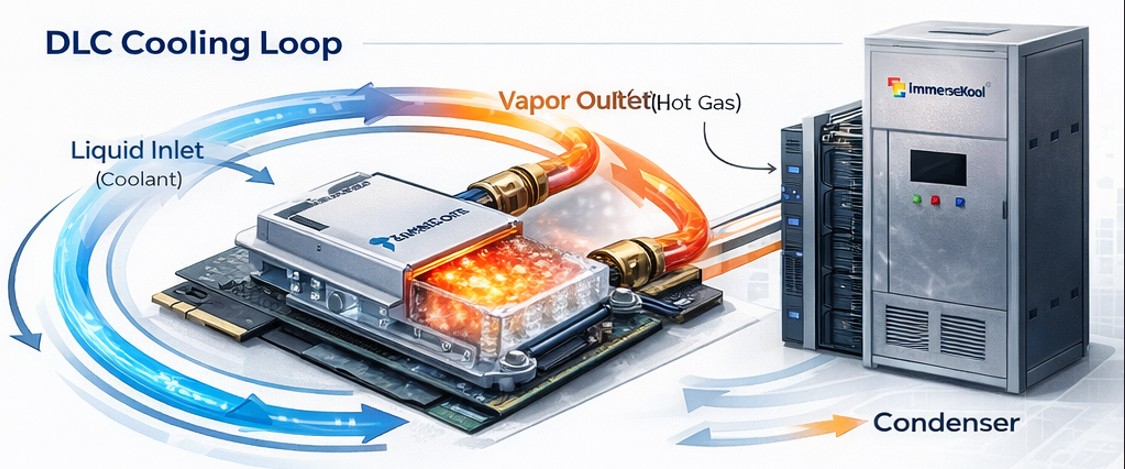

Two-phase DLC uses the latent heat of a dielectric coolant during phase change (liquid → vapor) to remove heat from high-power components.

Definition & Core Principle

- Cold liquid enters the cold plate on the chip → absorbs heat and boils → vapor goes to a condenser → returns to liquid in a closed loop

- Single-phase relies on temperature rise, while two-phase leverages phase change for much higher heat-transfer performance

Benefits

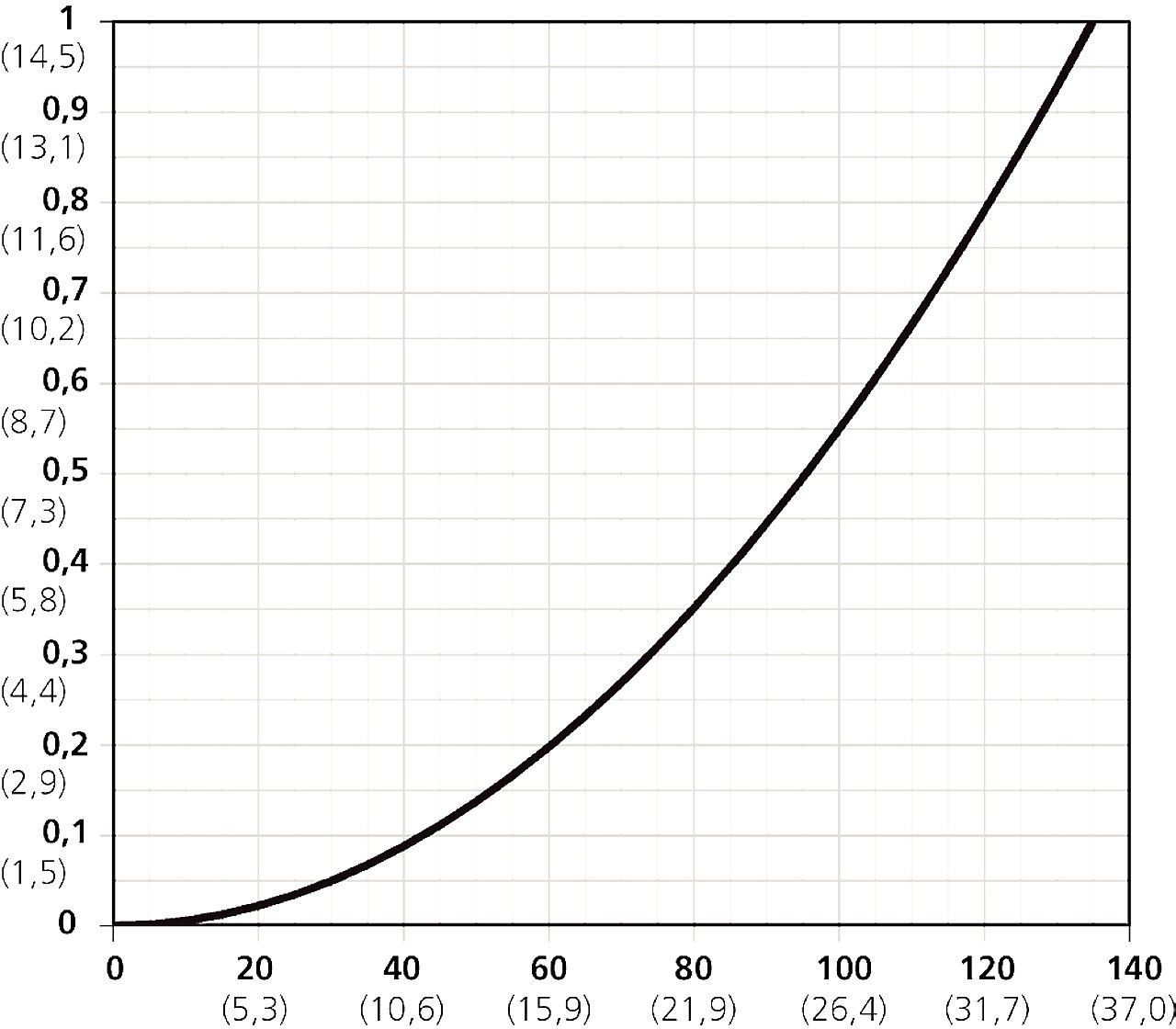

- Ultra-efficient: up to ~80% savings vs. air, ~50% vs. conventional liquid cooling (target PUE ~1.03)

- Supports high density: next-gen GPUs with 1,500–2,000W+ TDP

- Reliability: dielectric coolant mitigates hardware risk in case of leakage

- Lower pumping requirement: reduced pumping power can improve efficiency and lifetime

- Space optimization: higher rack density can reduce floor area

CEJN Quick Couplings (for Two-Phase DLC fluids)

CEJN develops dedicated quick couplings validated for two-phase DLC fluids such as R-1233zd.

- DN12 / 3/4" connection

- Aluminum + alloy composite material

- Special 587 series with PTFE/EPDM seals