In-Rack Liquid Cooling system

Specifications

| Cold Plate | Direct-to-chip (CPU/GPU) |

|---|---|

| Manifold | Rack mounted distribution |

| CDU | In-rack (row/room heat rejection) |

| PUE | ~1.2 / target < 1.2 |

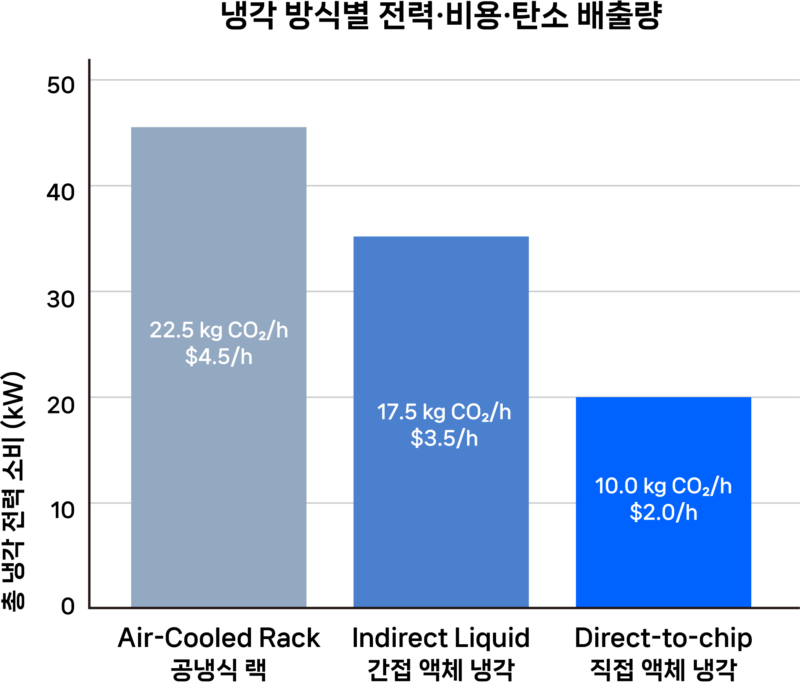

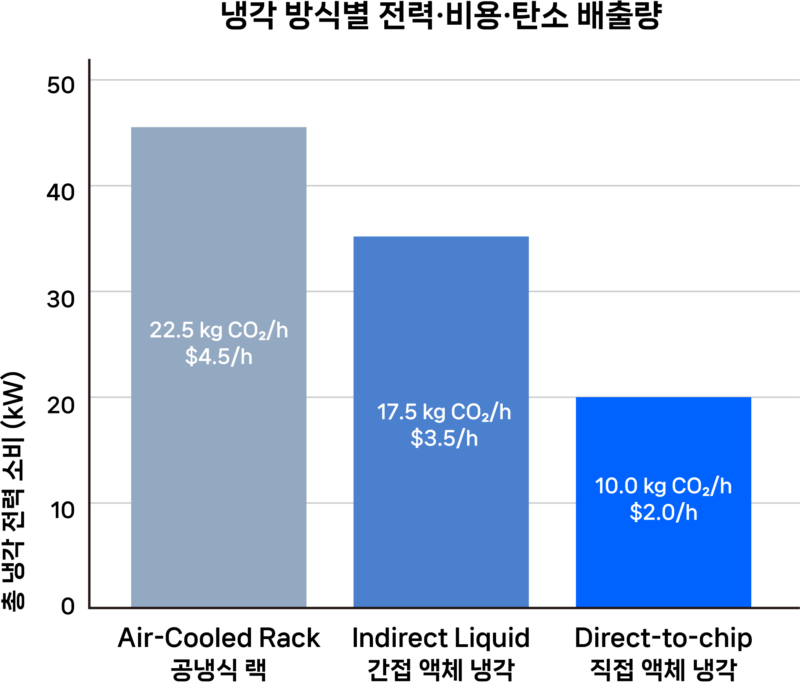

Direct-to-Chip (DLC) delivers coolant directly to high-heat components such as CPUs/GPUs. With a CDU and heat exchanger, coolant absorbs heat through cold plates and circulates in a closed-loop system.

Unlike immersion cooling, DLC cools only the target components through cold plates—without submerging the entire server.

| Cold Plate | Direct-to-chip (CPU/GPU) |

|---|---|

| Manifold | Rack mounted distribution |

| CDU | In-rack (row/room heat rejection) |

| PUE | ~1.2 / target < 1.2 |

| Per rack | High density racks supported |

|---|---|

| CDU | In-row (shared distribution) |

| PUE | ~1.2 / target < 1.2 |

| Notes | Facility water to dry/adiabatic cooler |

As AI servers push 300–400W+ per chip, air cooling alone reaches its limits. DLC reduces fan and air-handling load, improves chiller load and room temperature control, and boosts overall data-center efficiency.