Overview

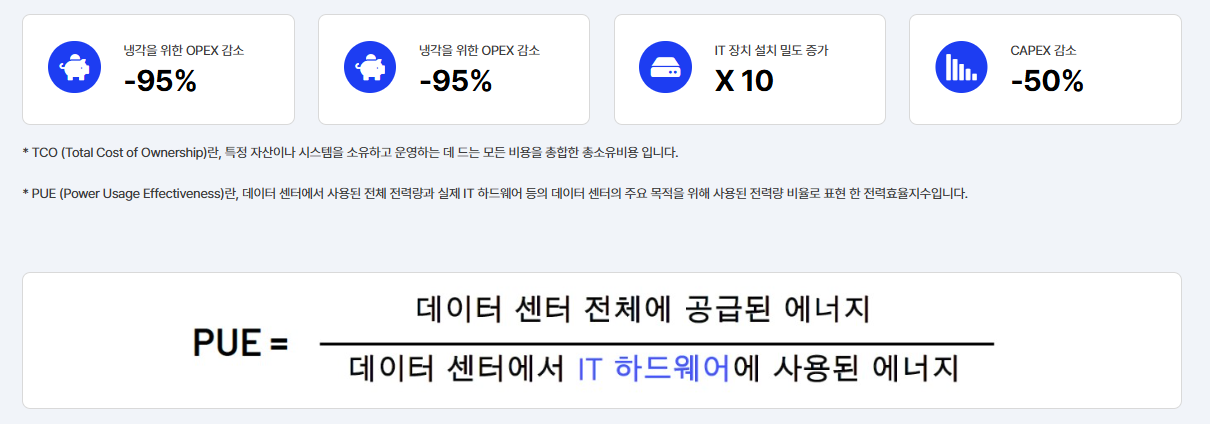

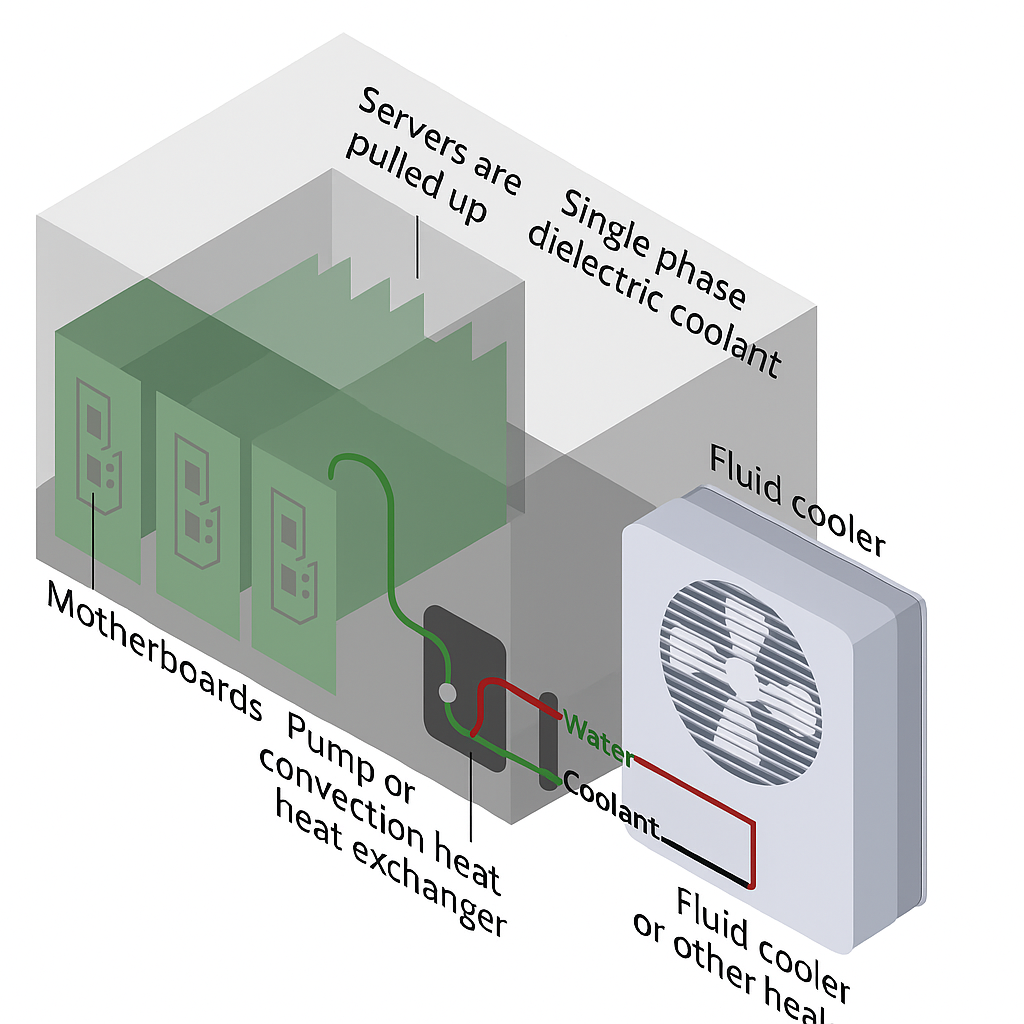

Single-phase immersion cooling submerges electronic equipment in a dielectric fluid to remove heat. Globally, average data-center PUE is still around 2.0, meaning cooling and facility overhead can consume energy comparable to IT load. Immersion cooling can significantly reduce cooling power, helping lower TCO and mitigate carbon emissions—depending on design and operating conditions.